by wsi | Déc 1, 2022 | Presse

Serviplast is rising to the energy challenge The climate and energy crises we are currently experiencing reinforce the need and urgency for transformation of manufacturing models. This is a real challenge that companies are facing. At Serviplast, since 2018 we have...

by wsi | Juin 18, 2021 | CASE STUDIES, Pièce assemblée

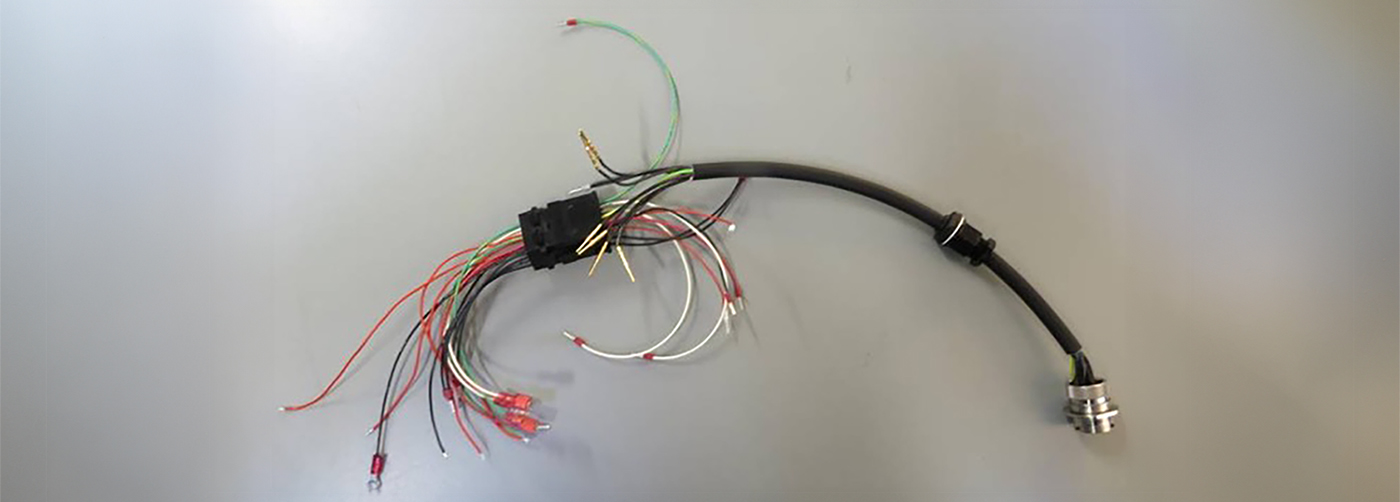

Thanks to their quality system and mastery of the production process, Serviplast Industrie assembles and packages electro-stimulation medical devices. By mastering its processes, Serviplast Industrie ensures the traceability of products from reception to shipping A...

by wsi | Mai 6, 2021 | CASE STUDIES, Pièce injectée

A project that saves money and is good for the environment. How did Serviplast Industrie combine aesthetic appeal, functionality, reduced costs and respect for the environment for Distrimarks’ soap box? Plastic injection via the hot runner technique Distrimarks is a...

by wsi | Avr 15, 2021 | CASE STUDIES, Pièce injectée

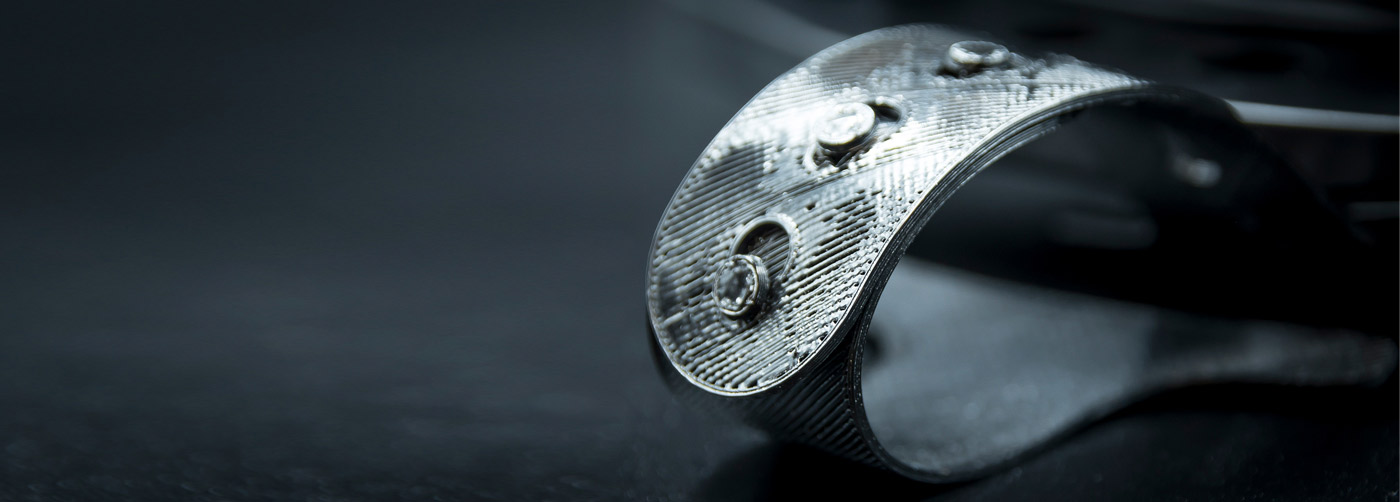

Vermeire Belting called on Serviplast Industrie’s tooling expertise to produce six flanges for three rolling bearing models. Discover what Serviplast did to optimise costs within the given deadlines. Six parts for a single tool: how to break the mould? Vermeire...

by wsi | Mar 24, 2021 | CASE STUDIES, Pièce assemblée, Pièce imprimée en 3D, Pièce injectée

Serviplast Industrie has developed a comprehensive solution for the Armosa box tree moth trap system: prototyping, plastic injection and packaging. 3D-printing prototyping for a perfect fit Armosa is a company that develops innovative solutions to protect people,...