A project that saves money and is good for the environment. How did Serviplast Industrie combine aesthetic appeal, functionality, reduced costs and respect for the environment for Distrimarks’ soap box?

Plastic injection via the hot runner technique

Distrimarks is a Belgian company that produces and distributes cosmetics products, in particular Vita Verde products. Distrimarks called on Serviplast Industrie to produce a Vita Verde soap box.

After studying the industrialisation process for this part, Serviplast Industrie’s design office drafted plans for three soap box models using CAD software. Distrimarks was happy with these proposals and chose one of the three models. Serviplast Industrie then produced a prototype via 3D printing. This made it possible to perform the necessary functional tests.

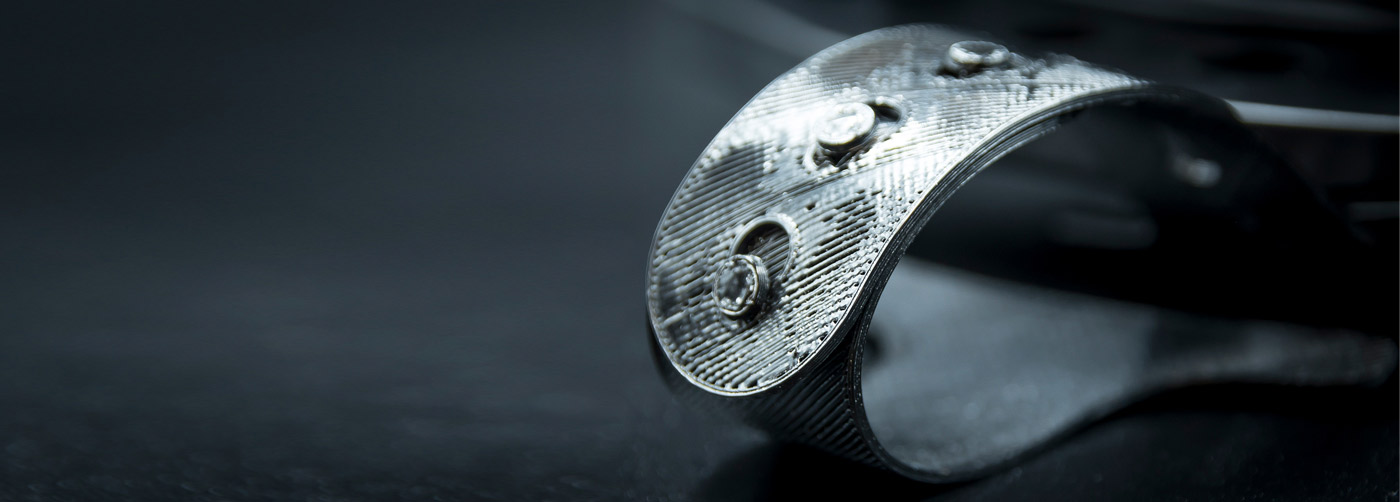

After optimising the part, tooling could finally be manufactured! As this project involved a cosmetic product that would be sold, a seamless blend of aesthetic appeal and functionality was required. The soap box needed to be made from a material that was flawless and pleasant to touch, while also fulfilling its practical applications. This is why Serviplast Industrie’s experts opted for a hot runner mould with a valve.

The benefits:

- saving money by reducing waste: there is no need to produce an injection gate;

- the injection point has greater visual appeal.

Contract fulfilled for Serviplast Industrie, with the added advantage of having a more environmentally responsible injection system due to the reduced amount of plastic waste produced.

The environmentally responsible choice of plastic for a perfect finish

Using recycled plastic was an obvious choice for Distrimarks as it is good for the environment. Serviplast Industrie encouraged this idea, having recently received the Socially Responsible Company label.

To this end, Serviplast Industrie used its expertise to identify and find the perfect material to satisfy all the functional and aesthetic requirements of the product: 100% recycled polystyrene (PS). Recycled PS has the advantage of retaining all the advantages of virgin PS: lightness and durability.

The art of finding unique plastic-injection solutions

Thanks to Serviplast Industrie’s expertise, Distrimarks has a bespoke plastic-injection part that satisfies its request: a beautiful product that does not sacrifice functionality or environmental responsibility.

The Serviplast Industrie team always goes the extra mile for your plastic-injection project, in order to find the BEST solution for you. To this end, Serviplast Industrie offers additional services to meet your needs: connections, technical assembly, packaging, shipping and more.

Ask our team for advice!