Serviplast Industrie has developed a comprehensive solution for the Armosa box tree moth trap system: prototyping, plastic injection and packaging.

3D-printing prototyping for a perfect fit

Armosa is a company that develops innovative solutions to protect people, plants and animals against pests. Armosa called on Serviplast Industrie to develop and produce its new product for combating box tree moths.

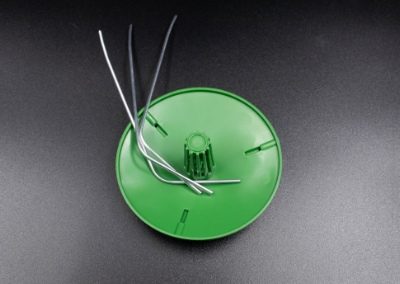

What made this project unique was creating an effective system that made it possible to accommodate several types of pheromone-soaked tabs. The pheromone attracts the box tree moth to the trap, which prevents caterpillars from reproducing.

Effectively holding the tabs in place was a key consideration when developing this trap. In order to produce an effective solution, Serviplast Industrie’s design office:

- studied the industrialisation of the trap in its entirety;

- optimised the design of the trap by simulating the injection;

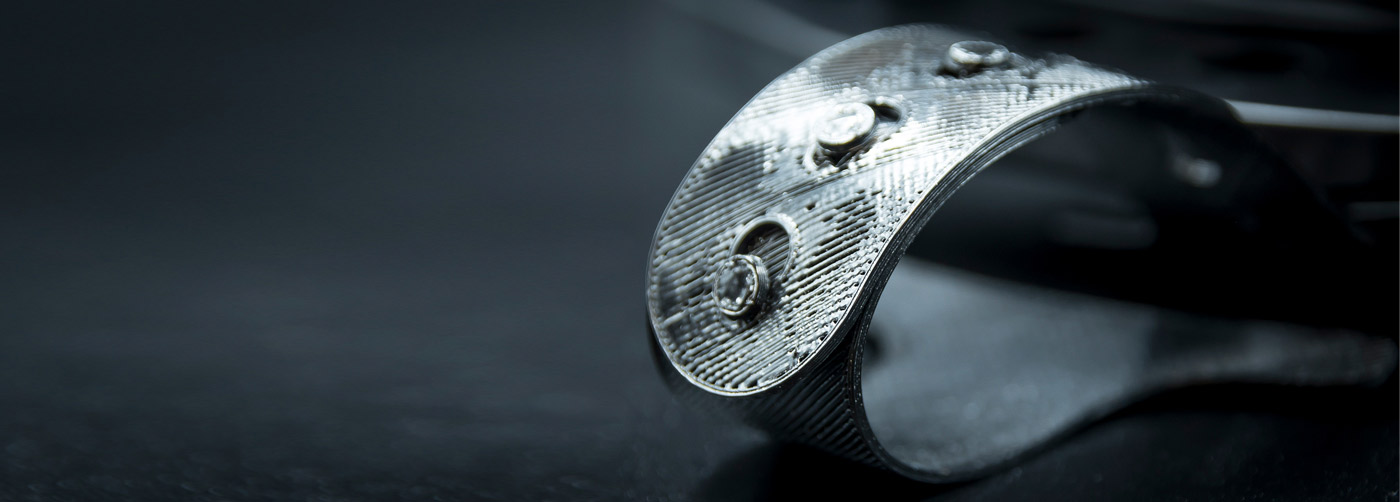

- created prototypes via 3D printing with a variety of connectors, in order to simulate how the tabs are held in place;

- improved the model until the ideal prototype had been produced.

After multiple tests, the mould was created and the parts were manufactured via plastic injection.

Preparing the kit: a mixture of plastic and metal parts

The trap is made of three plastic parts, which were developed and produced by Serviplast Industrie, as well as six bent or straight metal parts. Serviplast Industrie worked with one of its suppliers to produce these metal parts. This is an easy solution for Armosa, as they do not need to handle ordering the parts or the delivery!

Packaging the kits involved two stages:

- bagging plastic and metal parts;

- packaging the kits.

Serviplast Industrie is used to packaging products in its workshops for both regular or one-time orders, in small or large batches. As a result, Armosa benefited from our packaging expertise.

From mastering prototyping to packaging – the bespoke way!

Thanks to a comprehensive service offering that includes developing plastic parts, ordering metal parts and packaging kits in bags and boxes, Armosa has ensured:

- the ingenuity of the tab-attachment system;

- the speed of the production process;

- the centralised packaging of plastic and metal parts.