by Evelyne | May 6, 2021 | CASE STUDIES, Injected Part

A project that saves money and is good for the environment. How did Serviplast Industrie combine aesthetic appeal, functionality, reduced costs and respect for the environment for Distrimarks’ soap box? Plastic injection via the hot runner technique Distrimarks is a...

by Evelyne | Apr 15, 2021 | CASE STUDIES, Injected Part

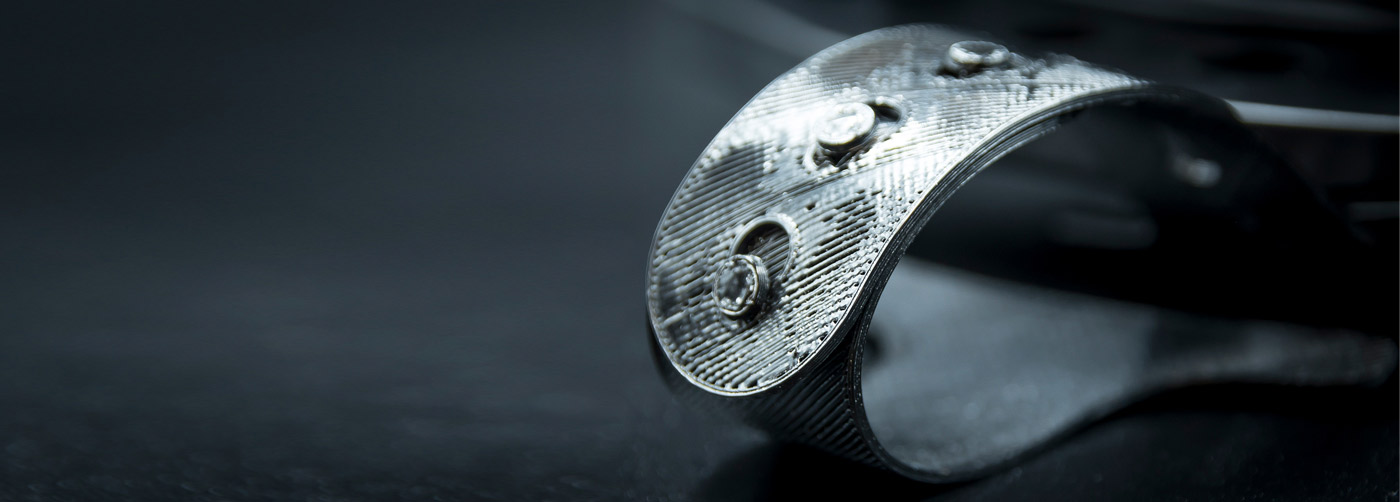

Vermeire Belting called on Serviplast Industrie’s tooling expertise to produce six flanges for three rolling bearing models. Discover what Serviplast did to optimise costs within the given deadlines. Six parts for a single tool: how to break the mould? Vermeire...

by Evelyne | Mar 24, 2021 | Assembled Part, CASE STUDIES, Injected Part, Printed Part

Serviplast Industrie has developed a comprehensive solution for the Armosa box tree moth trap system: prototyping, plastic injection and packaging. 3D-printing prototyping for a perfect fit Armosa is a company that develops innovative solutions to protect people,...

by Evelyne | Oct 13, 2020 | CASE STUDIES, Injected Part, Printed Part

]Innovation chez Serviplast : une pièce plastique technique injectée dans un moule réalisé en impression 3D métallique. Grâce à sa collaboration avec l’entreprise luxembourgeoise Simaform, Serviplast apporte à ses clients gain de temps et coût de fabrication réduit....

by wsi | Oct 30, 2019 | CASE STUDIES, Injected Part

Specialised in invisible fixing systems for the outside decking and cladding, B-Fix wanted to develop a new part in order to improve the indoor ventilation of its wood structures. Mission accomplished ! Serviplast mobilized its expertise to design and produce a part...

by wsi | Apr 18, 2018 | CASE STUDIES, Injected Part

France’s National Real Tennis Federation asked Serviplast to create its new ball and glove insert. Serviplast put its design office and entire production chain behind the project. The client’s request – France’s National Real Tennis Federation sought to replace...