Charles: Logistics Manager

Charles came to Serviplast Industrie as a Warehouse Operator in 2021, with a solid background in mass distribution. His Logistics Manager decided to leave the company in January 2023. He seized this opportunity and underwent a training programme to take over the role. Thanks to his motivation, he was officially promoted to Logistics Manager.

When asked how his new role is going, Charles responds enthusiastically: ‘I really appreciate the variety in my job, and the chance to learn new things every day. Above all, though, what motivated me to throw myself into it wholeheartedly is that the company gave me an opportunity and trusted me.’

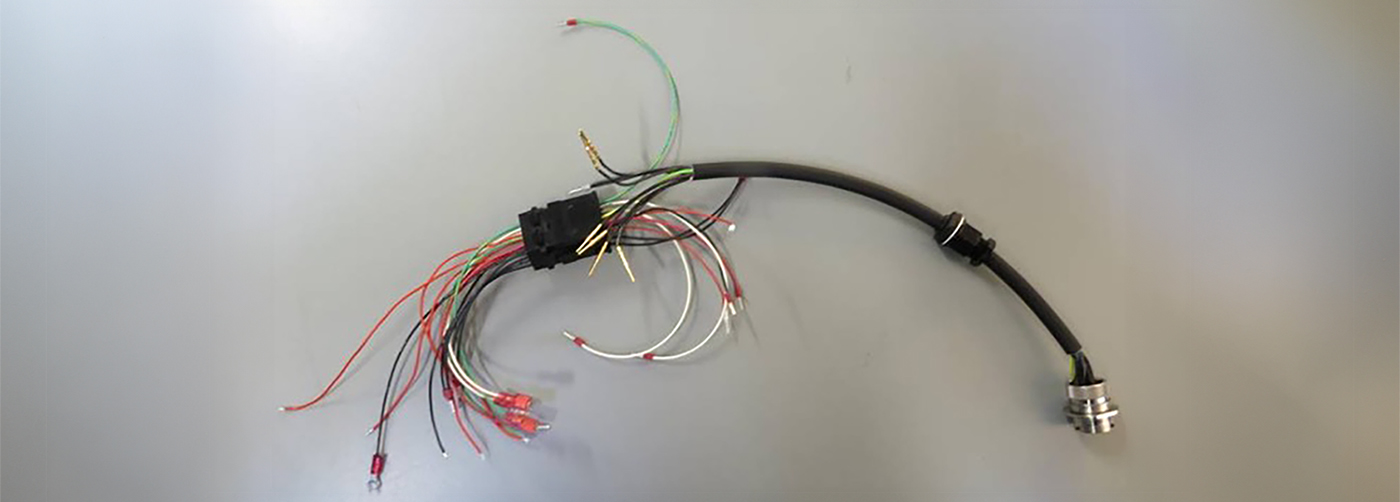

Charles’ job: essential for the traceability of parts and components

Charles receives the goods, inspects them, and enters them in the management system (ERP) to ensure they are traceable.

He is responsible for managing the different storage areas. This involves efficiently organising storage locations and ensuring that products are correctly identified and in the right place. He ensures that the FIFO (First In, First Out) principle is applied when managing inventory. This means that products are used and shipped based on the date they were received.

He prepares production orders and ensures that materials are available in the required quantities.

He regularly takes stock of the inventory, in order to ensure physical stocks and the data in the ERP system align and to prevent discrepancies or shortages as a result.

Charles is also responsible for managing and organising shipments of finished products to customers: he coordinates the means of transport, prepares shipping documents and ensures the customer’s deadlines are met.

Clients can outsource the logistics for their webshop with Serviplast Industrie. Charles also handles any shipments to the end user stemming from orders on the website.

The goals of the Logistics Manager

The Logistics Manager ensures that several goals are achieved within Serviplast Industrie:

- guaranteeing a smooth and reliable supply chain;

- ensuring the monitoring and precise management of stock to avoid shortages;

- avoiding untimely production stoppages by ensuring the availability of the necessary components and products;

- ensuring compliance with the relevant deadlines by organising and planning shipments in an optimal manner;

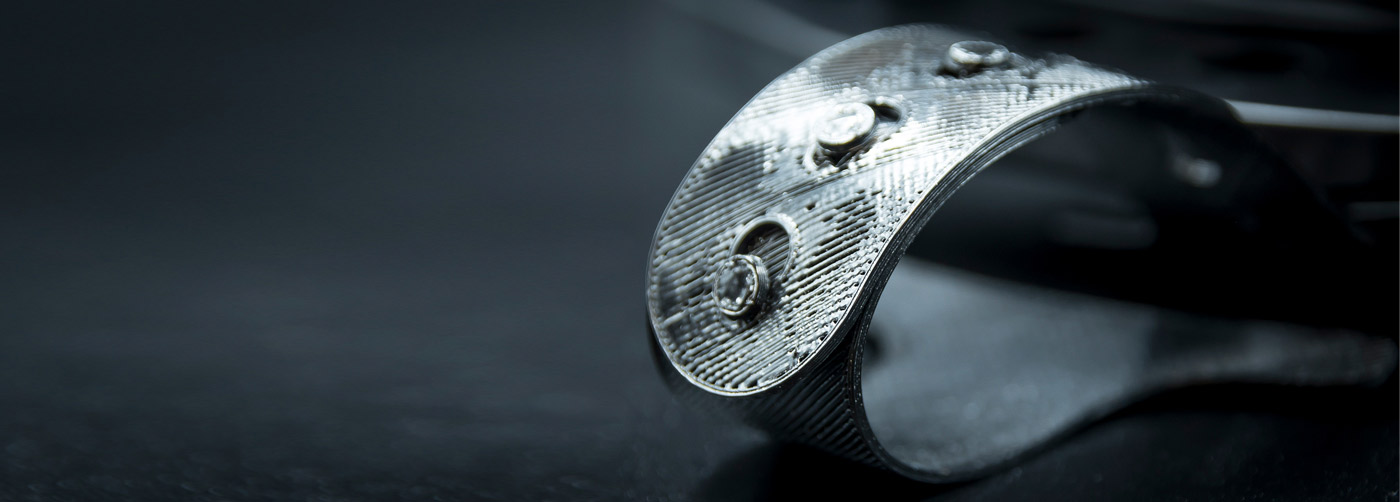

shipping the finished products to customers around the world in a reliable fashion.

By ensuring optimal logistics management, Charles plays a key role in the smooth running of production lines and the delivery of parts to the customer.

Would you like our advice and expertise for your custom production project?