Maintaining the moulds in order to guarantee the quality of the plastic parts produced

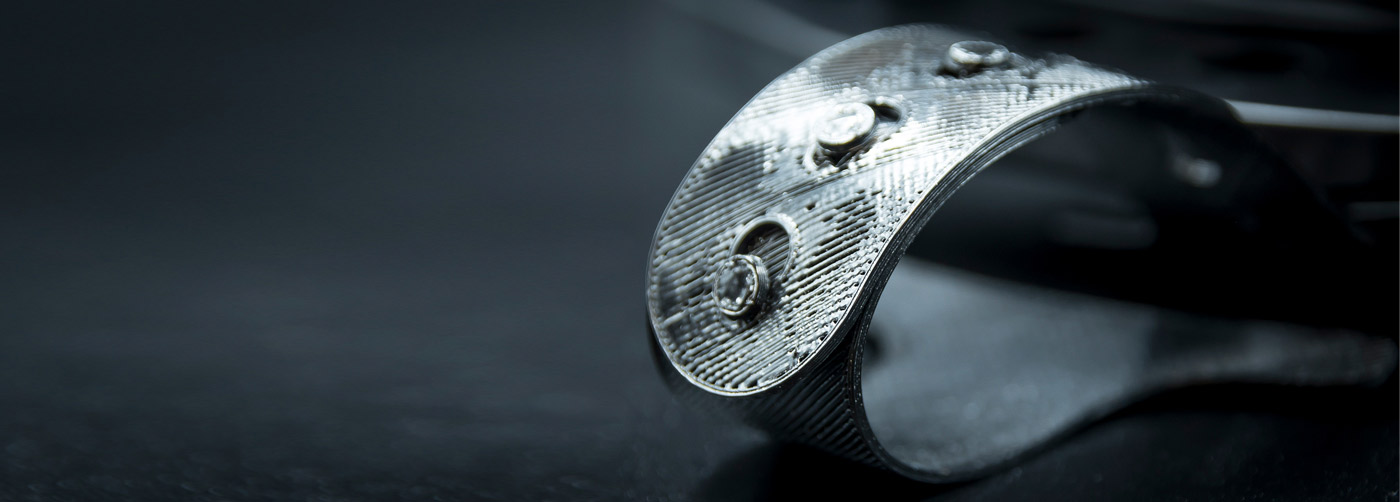

Moulds are essential machined parts for the production of plastic parts. These bespoke products require regular maintenance to ensure they work correctly. Indeed, poorly maintained moulds can cause manufacturing defects in the parts, such as burrs.

Since they are experience, replacing them represents a significant financial investment. Regular maintenance makes it possible to extend their lifespan. This is what makes maintenance technicians so important.

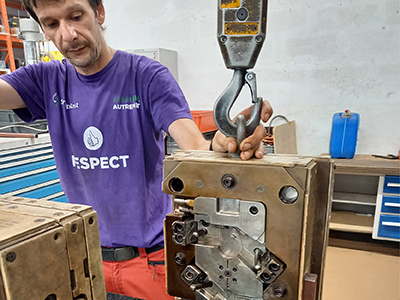

Christophe: a Tooling Maintenance Technician at Serviplast Industrie

Christophe trained as an electrician and came to Serviplast Industrie as a Plastic Injection Operator in 2016. He subsequently worked in the special services team. Today, Christophe is training with the technical team as a maintenance worker.

This change of profession fits him like a glove: ‘I really enjoy this role as a maintenance technician. I like the variety in the work, and the rigour and precision of it. If I have any questions, my manager is always on hand and takes the time necessary to answer them.’

Christophe’s job: a key aspect of maintaining optimal results from moulds

Before production begins, Christophe prepares the tools. This involves carefully setting up the moulds and ensuring they are ready for use. This initial step is key to ensuring the quality and conformity of the plastic parts that will be manufactured.

Once production is complete, he cleans the moulds to remove any residue. He uses special tools, such as ultrasonic baths and fountains with solvent, to ensure they are cleaned properly and completely.

A marble work table is used to carry out meticulous inspections. In addition, the appropriate handling devices, such as hoists, are used to safely handle the moulds.

Christophe then stores the moulds in their designated area. A specific ID in the management system (ERP) makes it possible to locate them quickly.

The goals of the Tooling Maintenance Technician

The role of the Tooling Maintenance Technician is key to achieving several goals within Serviplast Industrie’s plastic injection business unit.

Ensuring tools are in good condition guarantees that the parts manufactured are of high quality.

- Regular maintenance increases the lifespan of these tools.

- Maintaining the tools in good condition helps to avoid untimely shutdowns during production.

By helping to keep the tools in perfect condition, Christophe is actively contributing to the overall success of Serviplast Industrie.

Would you like our advice and expertise for your custom production project?