YOUR PROJECT,

LED BY OUR EXPERTS

An expert in plastic injection, complementary professions and support from the design phase through shipping

Serviplast Industrie assists you with researching and prototyping your project, 3D printing, tooling, plastic injection, technical assembly operations and customised packaging.

AN INTEGRATED THREE-STEP PROCESS

Our three-step project management ensures compliance with deadlines and a part that meets your requirements. In practice, the earlier we intervene in the development process, the more we are able to optimise your product from a technical and financial point of view.

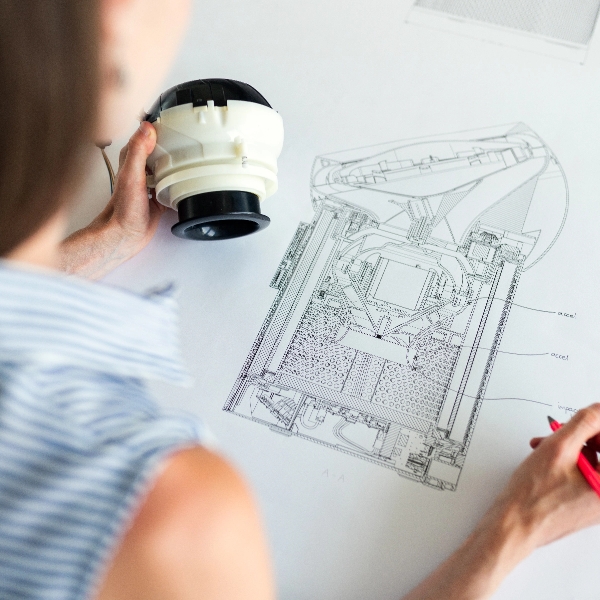

01TECHNICAL FEASIBILITY STUDY

We analyse your concept in detail, in order to :

- CARRY OUT A FUNCTIONALITY STUDY ;

- DETERMINE THE MOST APPROPRIATE MANUFACTURING PROCESS (PLASTIC INJECTION, 3D PRINTING) ;

- ANALYSE TOOLING NEEDS ;

- OPTIMISE INJECTION PARAMETERS VIA A SIMULATION TOOL.

Serviplast also considers eco-design solutions to minimise waste from production and encourage the reuse or recycling of parts and packaging.

02DEVELOPMENT AND 3D PROTOTYPING

If your project requires a prototype to validate functionality or other aspects of your part, we can produce it via 3D printing.

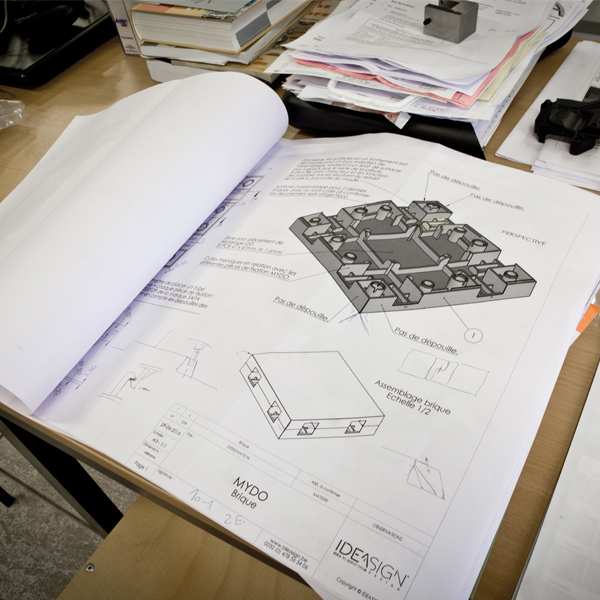

After this finalisation phase, we can begin designing and machining your mould. During this stage, assembly lines, workstation ergonomics and peripheral automation are developed as well.

03 TESTING AND VALIDATION

We draft measurement reports to ensure that the parts fulfil your requirements and specifications. Several correction loops may be required to finalise the mould and validate the production and quality parameters.

Serviplast drafts the process and quality sheets. A rigorous methodology ensures a reliable production process in the long term.

PERSONALISED, CERTIFIED AND RESPONSIBLE SUPPORT

From a quotation request to validation by the client, Serviplast Industrie implements a project-management methodology that aims to ensure the quality of your product and provide personalised support.

Serviplast Industrie is an ISO 14001 certified company and encourages eco-design when developing products. Your requirements and our goal? Minimising production waste, favouring degradable or bio-based materials, optimising the life cycle of products and encouraging the recycling of parts and packaging.

CERTIFIED QUALITY

Having an ISO 9001 certified partner guarantees compliant and traceable products. Serviplast implements a rigorous and guided approach for its processes.

01STANDARD INSPECTION IN THREE PHASES

A specialised ‘quality agent’ carries out an initial inspection during production (First Piece Check) and a second inspection upon completion (Last Piece Check). Our operators also intervene during production to carry out an inspection via sampling.

02INSPECTION UPON REQUEST

An audit is required during production.

03FULL INSPECTION

You define the criteria and we inspect each part.

PRODUCTION IN THE CIRCULAR ECONOMY

We support the circular economy approach by implementing it at each step in your project.

DESIGN AND CHOICE OF SUSTAINABLE MATERIALS

Thanks to our expertise in eco-design (development and manufacturing) on both aesthetic and functional levels, we can produce your part in an environmentally responsible way. This also involves choosing materials in keeping with the purpose of the part that are sufficiently sustainable. These materials can be bio-sourced, biodegradable, recycled and recyclable.

PRODUCTION AND PACKAGING

During production, we strive to reduce our environmental impact by optimising injection parameters and energy needs. The choice of packaging is also important; it must be eco-friendly.

A CIRCULAR APPROACH

We provide all the information you need to analyse the life cycle of the parts produced. For a complete circular approach, our design partners integrate every aspect – repair, reuse, recycling – of your product.

Need personalised advice ? Our experts support you throughout your project.

WHAT DO YOU WANT TO PRODUCE ?

YOUR INJECTED PART

YOUR ASSEMBLED PART

YOUR PRINTED PART

A global offer to benefit your industrial project

THEY TRUST US

READY TO GET STARTED ?

Come and discuss your project with us.