New at Serviplast Industrie: 3D printing TPU. Make durable and flexible parts and take advantage of the benefits of 3D printing.

A flexible and robust material that works for all sectors

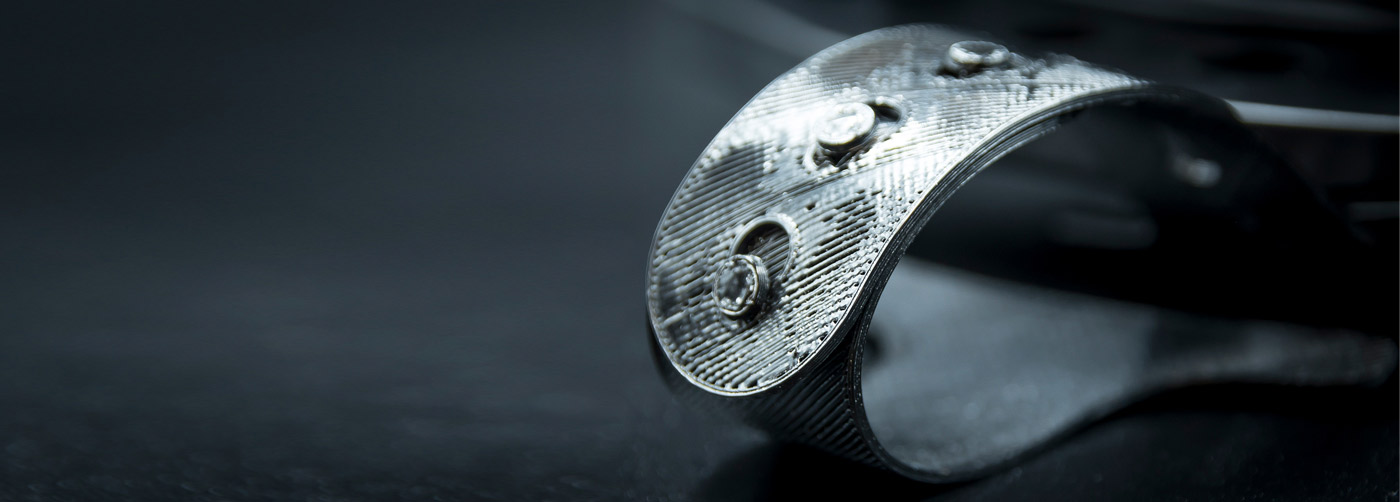

TPU is a flexible thermoplastic polyurethane. It is ideal for producing flexible parts. Thanks to its Shore hardness rating of 92A, TPU used for 3D printing adds a great deal of resilience to the parts that are produced.

Although it is flexible, this soft material offers several advantages when it comes to durability. TPU is highly resistant to wear and tear and abrasion. TPU parts are also resistant to oil, solvents and scratches. As a result, this versatile material may be used for a variety of applications.

Versatile TPU applications through 3D printing

TPU is ideal for flexible projects, such as washers, suction pads, mask straps, shock absorbers, soles for shoes, watch straps, phone cases, drone parts and more!

3D printing TPU makes it possible to produce more complex parts than traditional techniques. By reducing production costs and lead times for TPU parts, 3D printing offers significant opportunities for development in all sectors.

The choice of plastic for 3D printing

Thanks to its expertise in 3D printing, Serviplast now offers an extensive range of plastics (ABS, PA, PEEK, TPU, PC/ABS, etc.). This range of choices for 3D printing makes it possible to quickly produce prototypes for functionality tests.