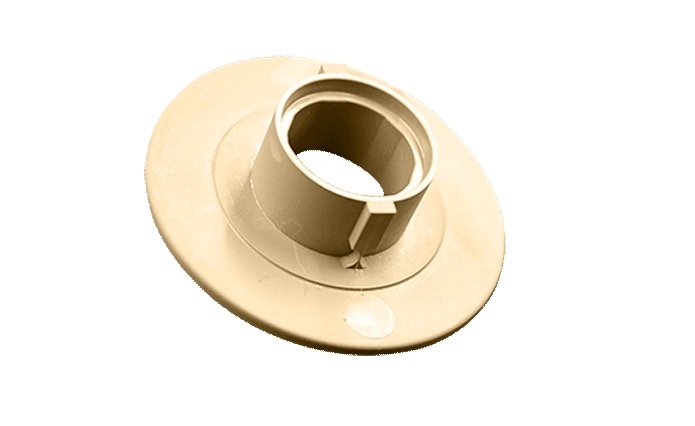

YOUR INJECTED PART

An injected part that meets your quality requirements, delivered on time and produced at a competitive price.

You need high-quality plastic-injection parts and a durable mould, all for a reduced price and with a lower carbon footprint. Serviplast Industrie ensures both technical and financial efficiency. Customised support, from the design to the injection of your part.

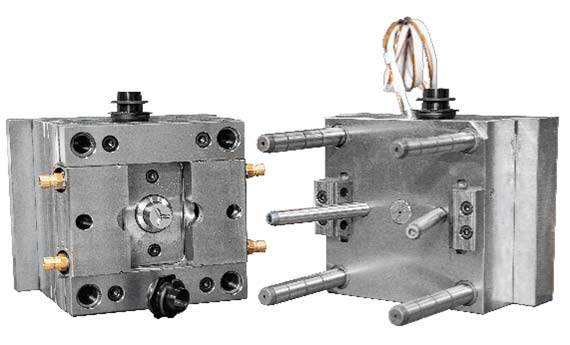

TOOLING

Your bespoke mould

Producing an injected part that satisfies your expectations requires tooling that has been designed and manufactured specifically for you. Design, prototyping, tooling and plastic injection – Serviplast works with you from the design phase of your part to optimise industrialisation.

We offer a solution in conjunction with our network of partners, based on your technical requirements and budget.

Serviplast manages your tooling from beginning to end, from the design to the production of the mould.

We also handle the maintenance of your tooling and store it under the best possible conditions, in order to optimise the life cycle of your mould.

MACHINED MOULDS

The type of part, its use, the injected material, the durability of the tooling – we evaluate every aspect of your project to find the best tool-maker for your needs. Serviplast Industrie relies on a large network of partners, who are selected based on the technical specifications of your project.

3D-PRINTED MOULDS

An ideal alternative for producing smaller parts, with a reduced production time and lower costs. An innovative solution.

MATERIALS

A crucial step for your project

The function of the part defines the material you choose. The thickness of the part, the texture, its flexibility, its transparency, the colour, its resistance to heat – these are all key factors. Serviplast Industrie offers its in-depth expertise in plastic injection by providing a wide range of plastic materials :

TECHNICAL MATERIALS

PEEK, PA, PA+GF, TPE, TPU, …

MATERIALS TRADITIONAL

PE, PP, PC, PC/ABS, ABS, …

MATERIALS INNOVATIVE

BIO-BASED AND BIODEGRADABLE

MATERIALS RECYCLED

PE, PE/PP, PS, …

PLASTIC INJECTION

Your project has taken shape. It’s time for your part to come to life

We rely on our 35 years of experience in plastic-injection processes to

produce small, medium and large batches.

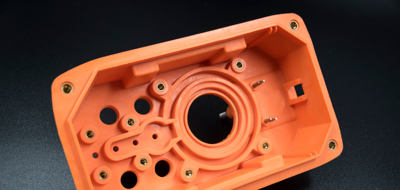

AUTOMATIC INJECTION

Our equipment allows us to produce precision technical parts with guaranteed repeatability. The parts are gripped by robots, with the possibility of a peripheral-automation system.

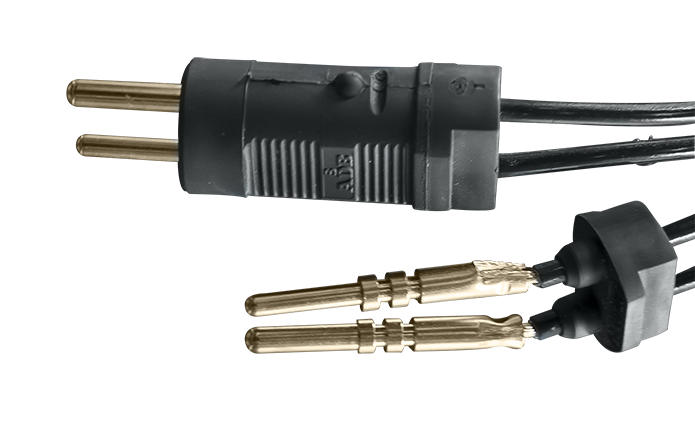

OVERMOULDING

We have developed expertise in the overmoulding of inserts, connectors and cables, thanks to the implementation of specific equipment for these operations. We also produce the various assemblies for overmoulding in-house.

FITTING INSERTS

We also perform post-injection operations on your plastic parts, such as the fitting of inserts. This operation needs to be taken into consideration from the design stage.

MACHINE FLEET

Overview of our facilities

Serviplast Industrie has a regularly updated machine fleet for an end-to-end and adaptive mastery of injection processes. Our workshop comprises 25 presses, ranging from 10 to 300 tonnes, which allow us to inject materials from a few cm³ to more than 800 cm³.

Serviplast Industrie also has all the peripherals needed to work with materials at high temperatures.

QUALITY CONTROL

3D contact and 3D optical inspection machines help to inspect and validate your parts.

Our quality-control operations ensure the traceability of your product throughout the production process, from acceptance of the materials or components to the shipping of the final product. You need more than one part and we offer every assurance. Serviplast Industrie guarantees compliance with your specifications by satisfying every requirement in terms of approvals and certification. The results of these inspections are archived and can be sent upon request.

Serviplast offers the appropriate level of quality control for your product :

sampling, audit and full inspection

SERVIPLAST INDUSTRIE ALSO HANDLES PACKAGING, LOGISTICS AND THE MANAGEMENT OF YOUR WEB SHOP

Having reached the end of the production process, your parts are ready for assembly, boxing and placement on pallets for safe shipping.

PACKAGING

We handle the packaging of your parts in our workshop, based on your requirements. Serviplast always guarantees a set amount. Consider our eco-friendly packaging as well. We use recycled and recyclable containers to reduce the carbon footprint of our activities.

LOGISTICS

Don’t worry about logistics – Serviplast Industrie ships your parts worldwide, within deadlines and under optimal conditions. Your product is effectively distributed – that’s a guarantee.

WEBSHOP

You can outsource the logistics of your web shop to Serviplast Industrie. We handle all the shipments to the end user directly, based on requests made via the website. Accelerated inventory management : more efficient and cheaper.

CASE STUDY

QUE SOUHAITEZ-VOUS RÉALISER ?

YOUR INJECTED PART

YOUR ASSEMBLED PART

YOUR PRINTED PART

THEY TRUST US

READY TO GET STARTED ?

Come and discuss your project with us.