YOUR 3D-PRINTED

PART

3D printing : a solution for prototyping and producing a single part or a small batch

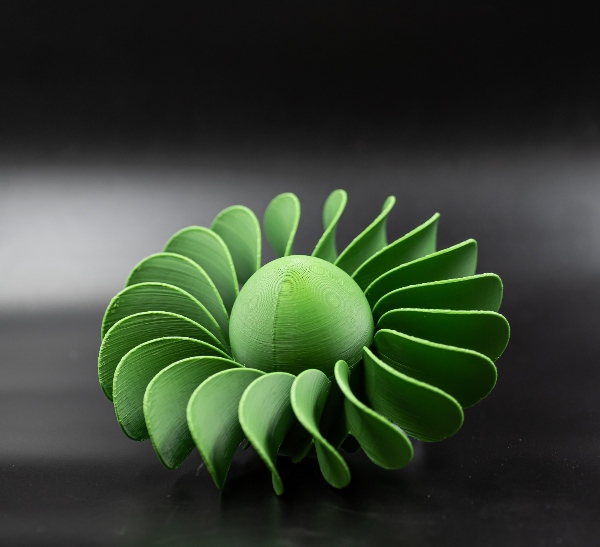

Have you designed a part that you want to preview as close as possible to its final form ? Does your request concern a single part, a small batch, or is it extremely complex ? Prioritise quick execution and reduced production costs with 3D printing. We will add a new dimension to your project.

PROTOTYPING

Prototyping ? This is a key step in finalising the design of your product and preparing for industrialisation !

Serviplast Industrie uses its mastery of the 3D-printing process to test the technical functionality of the part in real-life conditions. This allows you to view your model practically in its final form.

3D printing allows us to produce your test parts in a very short amount of time.

From the concept to the final form, you are guaranteed a part that meets your expectations.

A SINGLE PART

OR A SMALL BATCH

Do you need a single part for maintenance work or a specific project ? Need a small batch to market a limited production ?

3D printing is a good alternative to plastic injection, thanks to the reduced cost and accelerated production process.

MATERIALS FOR 3D PRINTING

Serviplast Industrie offers expertise in 3D printing different materials. Our team will suggest the appropriate material depending on the purpose of your project: plastic printing or metal printing.

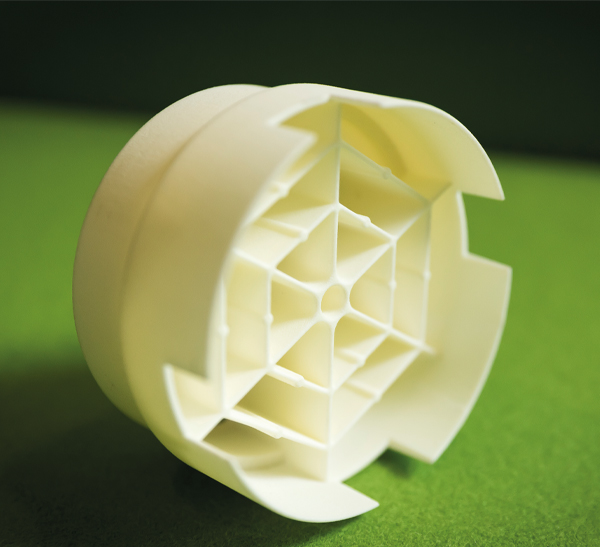

PLASTIC

Matériaux, finition et couleurs : notre équipe vous conseille dans vos choix fonctionnels et esthétiques. Serviplast Industrie vous propose une gamme complète de matières : PLA, PA12, PA6, ABS,…et du TPU qui est une matière souple.

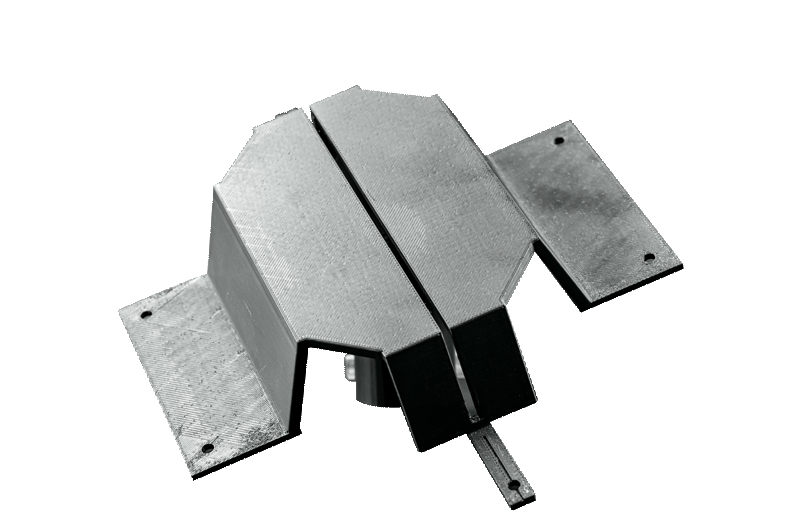

METAL

Dans le cadre de l'impression 3D métallique, nous travaillons avec l'acier maraging ou l'acier outil.

PRINTING PROCESSES

Your project is unique. We analyse every aspect – use, appearance, materials – to guide you towards the ideal production process.

PHOTOPOLYMERISATION

(RESIN-BASED)

LASER SINTERING

(POWDER-BASED)

FUSED DEPOSITION

(FILAMENT-BASED)

QUALITY CONTROL

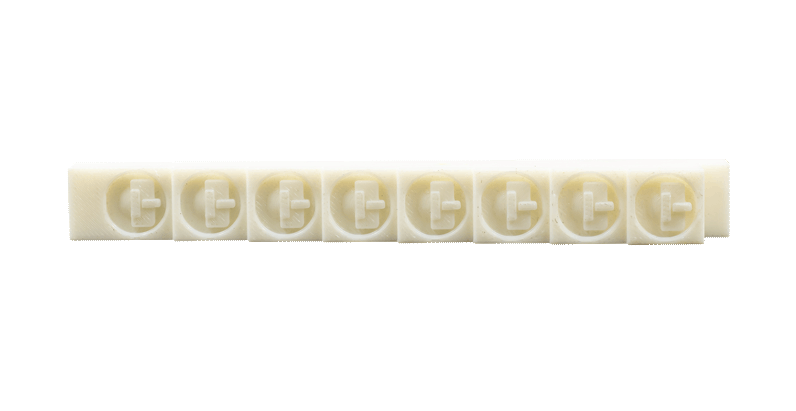

Serviplast Industrie incorporates the fitting of inserts during printing for the most complex fused-deposition printed parts. Our expertise satisfies the most exacting demands and the most innovative initiatives.

Serviplast Industrie ensures compliance with your specifications by fulfilling all of the requirements in terms of certifications and approvals. Serviplast Industrie offers quality control adapted to your product : sampling, audit, full inspection. The results of these inspections are archived and can be sent upon request.

SERVIPLAST INDUSTRIE ALSO HANDLES PACKAGING, LOGISTICS AND THE MANAGEMENT OF YOUR WEB SHOP

Having reached the end of the production process, your parts are ready for assembly, boxing and placement on pallets for safe shipping.

PACKAGING

We handle the packaging of your parts in our workshop, based on your requirements. Serviplast always guarantees a set amount. Consider our eco-friendly packaging as well. We use recycled and recyclable containers to reduce the carbon footprint of our activities.

LOGISTICS

Don’t worry about logistics – Serviplast Industrie ships your parts worldwide, within deadlines and under the best possible conditions. Your product is effectively distributed – that’s a guarantee.

WEB SHOP

You can outsource the logistics of your web shop to Serviplast Industrie. We handle all the shipments to the end user directly, based on requests made via the website. Accelerated inventory management: more efficient and cheaper.

CASE STUDY

QUE SOUHAITEZ-VOUS RÉALISER ?

YOUR INJECTED PART

YOUR ASSEMBLED PART

YOUR PRINTED PART

THEY TRUST US

Come and discuss your project with us.